How 3D Printing Is Revolutionizing Orthopedic Implants

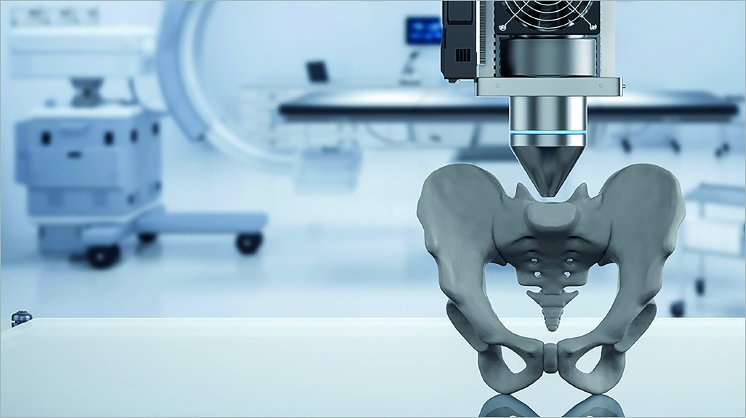

The world of orthopedic medicine has entered a new era, where personalization and precision are becoming the norm rather than the exception. One of the primary drivers behind this transformation is 3D printing technology, also known as additive manufacturing. This innovative technique has redefined how implants are designed, fabricated, and applied, particularly in complex or anatomically unique cases.

Among the leaders embracing this transformation are orthopedic implants manufacturers in Mexico, who are incorporating advanced 3D printing processes into their product lines to provide surgeons with more patient-specific solutions. This regional innovation is also helping bridge the gap between accessibility and high-performance medical technology in Latin America.

As the demand for ortho implants grows globally due to aging populations and active lifestyles, the traditional “one-size-fits-all” approach is being replaced by highly customized, biologically compatible, and functionally superior alternatives. And 3D printing is at the heart of this change.

What Is 3D Printing in Orthopedics?

In orthopedics, 3D printing refers to the layer-by-layer fabrication of an implant using computer-aided design (CAD) data, derived from imaging modalities like CT or MRI scans. The technology allows manufacturers and clinicians to produce anatomically precise parts that mimic bone structures and accommodate patient-specific geometries.

This capability opens doors for a wide range of applications, such as:

- Joint reconstruction, including hip, knee, and shoulder implants.

- Spine cages and fusion devices.

- Craniofacial and maxillofacial implants.

- Trauma plates tailored to unusual fracture configurations.

- Bone graft substitutes with porous structures that encourage bone ingrowth.

These applications reflect a shift in manufacturing and a paradigm shift in orthopedic treatment planning, execution, and outcomes.

Customization and Precision Fit

Traditional implants often come in standardized sizes, leaving surgeons to adjust the bone or soft tissue to achieve fitment. This can extend surgical time and increase patient trauma. With 3D printing, implants can now be custom-designed to match the patient’s unique anatomical structure, allowing for:

- Perfect alignment and reduced intraoperative adjustments.

- Shorter operation time and reduced blood loss.

- Minimized complications like implant migration or joint instability.

In trauma cases where bones have shattered irregularly or in reconstructive surgeries after tumor resections, the benefits of such tailored implants are even more pronounced. Surgeons can plan more accurately, conservatively cut bone, and improve long-term functional outcomes.

Improved Biological Integration Through Porous Structures

Another significant advantage of additive manufacturing is creating porous surfaces that mimic the natural architecture of cancellous bone. These porous implants encourage osseointegration—where natural bone grows into the implant—leading to stronger, more stable fixation.

Key benefits of porous design include:

- Enhanced biological response and faster healing.

- Elimination of the need for bone cement in many cases.

- Better load distribution and reduced stress shielding.

Traditional machining techniques cannot replicate these intricate lattice structures, making 3D printing the only viable method for producing such implants at scale.

Lightweight and Strong

The materials used in 3D-printed implants must meet strict biomechanical requirements. Titanium and its alloys remain the material of choice due to their high strength-to-weight ratio, corrosion resistance, and biocompatibility. With 3D printing, these materials can be layered to maintain strength while reducing unnecessary mass.

Recent innovations have also introduced:

- Hybrid implants, combining rigid outer shells with flexible, porous interiors.

- Bioresorbable polymers for temporary scaffolds.

- Composite materials that integrate antimicrobial coatings or drug-eluting properties.

These advanced material options improve the longevity of implants and minimize complications such as inflammation, infection, or allergic response.

Cost-Effectiveness and Reduced Waste

Contrary to the belief that 3D-printed implants are more expensive, the technology is proving cost-effective in the long run. Custom implants reduce the need for revision surgeries, minimize operating time, and lower inventory costs by reducing the sizes and models hospitals must stock.

Moreover, additive manufacturing is inherently efficient:

- Material use is optimized, with minimal scrap compared to subtractive machining.

- Rapid prototyping allows for faster development and shorter time-to-market.

- Digital files can be stored and reproduced as needed, reducing warehousing costs.

These efficiencies are especially valuable in emerging markets where budgets are constrained but the need for high-quality care is growing.

Surgical Planning and Simulation

The benefits of 3D printing extend beyond the implant itself. Surgeons can now use 3D-printed anatomical models to simulate complex procedures before entering the operating room. This hands-on rehearsal improves precision, reduces intraoperative surprises, and builds confidence among surgical teams.

Such preoperative planning tools have shown particular success in:

- Pediatric deformity correction.

- Oncology-related bone resections and reconstructions.

- Revision surgeries where bone stock is limited.

By merging diagnostics, planning, and implant production into a seamless workflow, 3D printing helps ensure that surgical outcomes are optimized from every angle.

Future Innovations and Global Accessibility

The 3D printing revolution in ortho implants is just beginning. Future innovations will include smart implants with embedded sensors that can monitor load, temperature, or healing in real time. Bioprinting—printing with live cells to create bone or cartilage structures—is also gaining traction in experimental settings.

To expand access, regional manufacturers are setting up localized production hubs that offer:

- Faster delivery of custom parts.

- Tailored solutions for the demographic and anatomical variations in local populations.

- Compliance with regional regulatory standards.

Collaboration between engineers, biomedical scientists, and clinicians will continue to push the envelope, ensuring that patients everywhere—from metropolitan hospitals to rural clinics—can benefit from precision medicine.

A New Standard in Orthopedic Care

3D printing is no longer futuristic but a reality transforming orthopedic care. With benefits ranging from better surgical fit and faster healing to cost savings and enhanced customization, this technology is rapidly becoming the gold standard in musculoskeletal medicine.

As more hospitals and clinics adopt these solutions, and as regional leaders in production like those in Mexico scale operations, the promise of a truly patient-centered approach to orthopedic surgery is being fulfilled. Surgeons now have tools that restore form and function and do so with elegance, efficiency, and long-term success in mind.